Fire Rated Glass for 45 Minute Applications

Understanding Fire Rated Glass for 45 Minute Applications

45-minute rated glazing applications continue to be a confusing area of the code, and it’s understandable given the several caveats and exceptions to its use. However, 45-minute glazing applications are where architects and building owners can find significant cost savings while increasing the level of protection. The key is to understand the codes and know the difference between various product options.

45 Minute Fire-Rated Glass Testing and Code Requirements

45 minute fire rated glass is used in fire protective doors, sidelites, transoms and openings that are tested to the following standards:

- NFPA 252, Standard Methods of Fire Tests of Door Assemblies

- NFPA 257, Standard on Fire Tests for Window and Glass Block Assemblies

- UL 9, Standard for Safety Fire Tests of Window Assemblies

- UL 10B, Fire Tests of Door Assemblies

- UL 10C, Positive Pressure Fire Tests of Door Assemblies

Architects and specifiers can turn to Chapter 7 of the International Building Code (IBC) for guidance on where 45-minute glazing is allowed:

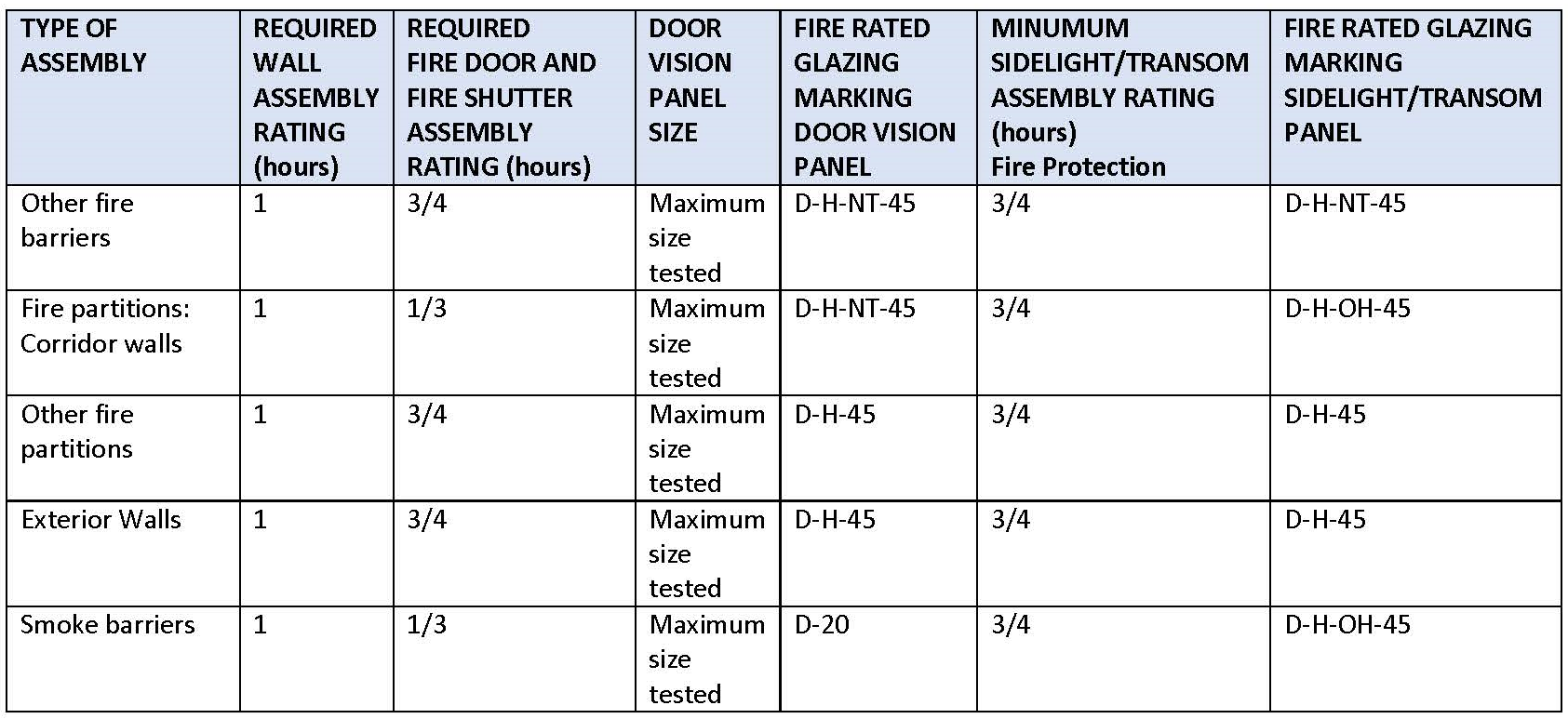

Excerpt from IBC Table 716.5 OPENING FIRE PROTECTION ASSEMBLIES, RATINGS AND MARKINGS

|

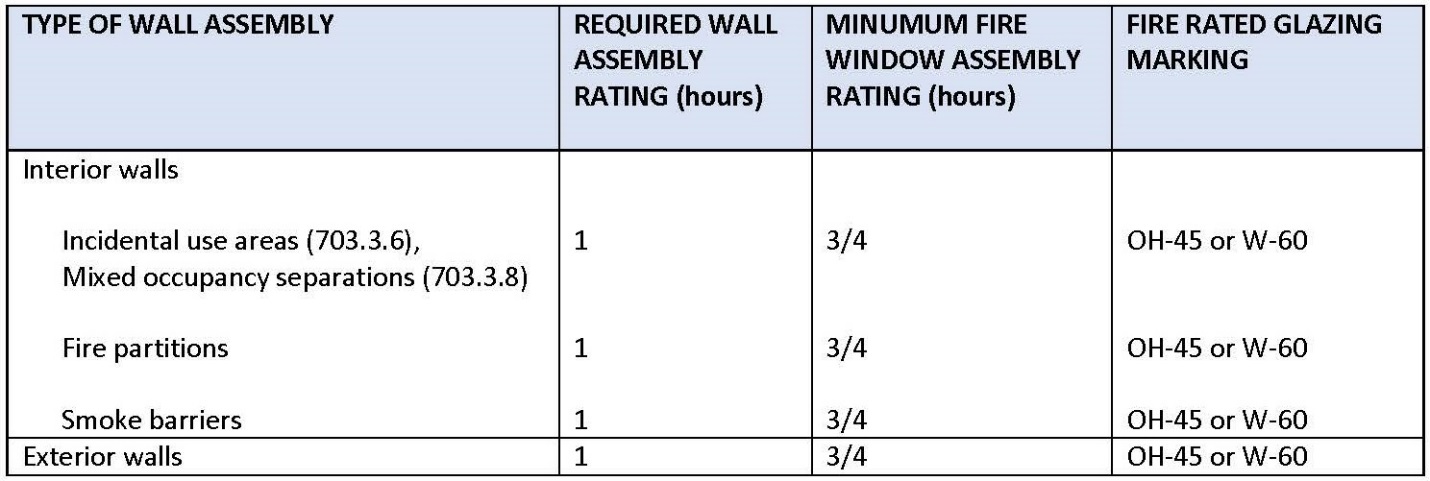

Excerpt from IBC Table 716.6 FIRE WINDOW ASSEMBLY FIRE PROTECTION RATINGS

|

The IBC limits the use of 45-minute glazing to 25% of the wall area because it blocks smoke and flames but not radiant heat. Additionally, it must meet ANSI Z97.1 and CPSC 16 CFR 1201 Cat. I or II impact safety requirements when used in doors, sidelites and other hazardous locations.

45 Minute Application Production Options

There are many product options for 45-minute glazing. While they all meet the same code requirements, they vary greatly in performance, appearance and cost.

Wired glass used to be the most commonly used product for this application, largely in part because it was the only available fire rated glazing at the time. It was mistakenly perceived as “safety glazing” because the embedded wires gave the illusion of increased strength and impact resistance, when in fact, the opposite is true. Wire actually weakens the glass, making it half as strong as ordinary annealed glass. It breaks easily on human impact, exposing razor -sharp wires that can trap a victim’s limb in the opening and increase the severity of the injury. This prompted several code changes that limited its use, and today the IBC states that wired glass cannot be used in doors, sidelites or any hazardous locations unless it meets the same impact safety standards governing all glazing products.

The emergence of the use of fire rated glass ceramic resulted in part due to the architects’ desire for wire-free glazing. However, like wired glass, it is extremely brittle and easily broken. As a result, it must be filmed or laminated to meet safety glazing requirements when used in doors, sidelites and hazardous locations.

Unlike wired glass, glass ceramic is expensive – in fact, of all the 45-minute glazing options, it has the highest cost, ranging from $100 to $120/square foot for the laminated version. Aside from a higher price and a fragile nature, glass ceramic typically has a tint that is quite different than float glass which cannot be removed no matter how much surface polishing the more expensive premium versions undergo.

The Best Clear Solution for 45 Minute Applications

The good news for architects and designers is that there is a readily available wire and tint-free 45-minute glazing option that meets all fire and safety requirements at a fraction of the cost of glass ceramics. SAFTIFIRST offers patent-pending SuperClear 45-HS-LI, a revolutionary optically clear, USA-made specialty fire protective product that meets UL 9, UL 10B, UL 10C, NFPA 252, NFPA 257, CAN/ULC S104 and CAN/ULC S106 with hose stream. It also meets CPSC Cat. II impact safety (the federal maximum) without the need for safety films or lamination. SuperClear 45-HS-LI is made with low-iron glass, with an approximate VLT of 90%. It has the same neutral coloration of float glass, it provides a uniform, tint-free appearance within a door assembly when used in sidelites and transoms alongside 20-minute doors glazed with economical specialty tempered glass. All of these advantages are available to designers and end-users at a fraction of the price compared to filmed or laminated ceramic used in the same 45 minute fire rated glass applications. To learn more about SuperClear 45-HS-LI, you can watch this short video.

|

| SuperClear 45-HS-LI (patent pending) in a 1 hour exit corridor at the The Quad at the University of Houston. |

If radiant heat is a concern for 45 minute applications, SAFTI FIRST has SuperLite II-XL 45, a clear, fire resistive glazing product tested to ASTM E-119, UL 263 and CAN/ULC S101. It meets the required hose stream test and provides full radiant heat protection. Like SuperClear 45-HS-LI, SuperLite II-XL is available with low-iron make-ups for superior optical clarity. It also meets CPSC Cat. II impact safety (the federal maximum) without the need for safety films or lamination.

For architects looking for an even more affordable, USA-made product for 45-minute applications, SuperLite I-XL 45 is another option. SuperLite I-XL 45 is a specialty tempered product that doesn’t have any amber tint typical of glass ceramics, meets CPSC Cat. II impact safety requirements and offers partial radiant heat protection. Here in the USA, SuperLite I-XL 45 must be submitted as an alternative fire rated glazing material to the AHJ (Authority Having Jurisdiction) under section 104.11 of the International Building Code because it is tested without hose stream (see footnote below).

Today, SuperLite I-XL 45 is accepted by the GSA (General Services Administration) and numerous AHJ’s across the US (see list) as an alternative fire rated glazing material in 45-minute applications for the many benefits that it offers. Building officials, designers and end-users accept the fact that at 45 minutes, radiant heat protection that allows for safe egress is far more important than meeting the hose stream test (see video – Radiant Heat: The Invisible Killer). There are several resources available on our website regarding SuperLite I-XL 45, including a Technical Bulletin that is designed for design professionals and AHJs.

If you have additional code or product-related questions, please do not hesitate contact our technical department at codesupport@saft.com. Our team of experts is ready to assist you with any current or upcoming project that you may have. You are also welcome to visit us online at www.safti.com or call us toll-free at 888.653.3333.

Footnote:

Building codes allow SuperLite I-XL 45 to be submitted to the AHJ (authority having jurisdiction) as an alternate material in 45 minute applications under Section 104.11 of the International Building Code:

104.11 Alternative materials, design and methods of construction and equipment. The provisions of this code are not intended to prevent the installation of any material or to prohibit any design or method of construction not specifically prescribed by this code, provided that any such alternative has been approved. An alternative material, design or method of construction shall be approved where the building official finds that the proposed design is satisfactory and complies with the intent of the provisions of this code, and that the material, method or work offered is, for the purpose intended, at least the equivalent of that prescribed in this code in quality, strength, effectiveness, fire resistance, durability and safety.

The commentary section further states that:

The code is not intended to inhibit innovative ideas or technological advances. A comprehensive regulatory document, such as a building code, cannot envision and then address all future innovations in the industry. As a result, a performance code must be applicable to and provide a basis for the approval of an increasing number of newly developed, innovative materials, systems and methods for which no code text or referenced standards yet exist. The fact that a material, product or method of construction is not addressed in the code is not an indication that such material, product or method is intended to be prohibited. The building official is expected to apply sound technical judgment in accepting materials, systems or methods that, while not anticipated by the drafters of the current code text, can be demonstrated to offer equivalent performance.