How Does Fire-Rated Glass Work? An Illustrated Guide

Even with the recent advances in material technology and safety standards, structural fires remain a constant threat to establishments everywhere. One report shows that 100,300 nonresidential fires are reported in the United States, resulting in an estimated 90 deaths and 1,350 injuries, as well as $2.4 billion in property losses per year.

Moreover, the same report found that fires spread beyond the room of origin in 59% of nonresidential fires. Confining the fire to where it started will save lives and prevent further economic loss . One way to mitigate the damage from a fire is by installing fire-rated glass in appropriate places. What’s great about fire-rated glass is that it lends both aesthetic appeal and functional safety to a structure.

The infographic below will help you understand how fire-rated glass works and how it improves a building’s structural integrity that can save lives in times of emergency.

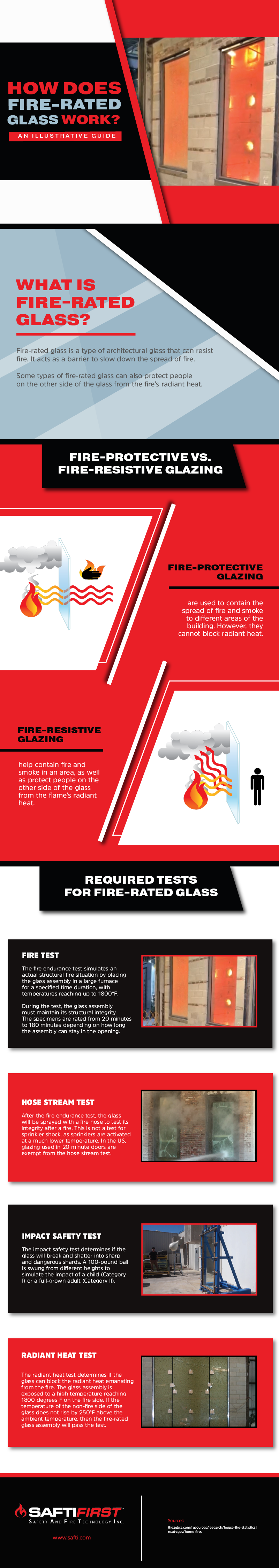

What is Fire-Rated Glass?

Fire-rated glass is a family of specialty glazings that have been proven to be resistant to fire. They act as a barrier, helping slow down fires and prevent their spread throughout the building. Some types of fire-rated glass also offer a degree of protection from the heat emanating from a flame (a.k.a. radiant heat).

Unlike common fire-resistant materials like bricks and concrete, fire-rated glazing lets light pass through to illuminate interior spaces, thus providing both form and function.

Fire-Protective vs. Fire-Resistive Glazings

Fire-rated glazings are subdivided into two categories: fire-protective glazing and fire-resistive glazing. Each type has its own set of features, standards, and applications.

A fire-protective glass, tested NFPA 252/257 or UL 9/UL 10C and typically rated from 20–45 minutes, is used to prevent the spread of fire and smoke to different areas of the building. However, products in this category do not prevent the heat from radiating through the other side of the glass. Since they cannot protect against radiant heat, fire-protective glasses cannot exceed 25% of the total wall area as per the building code. They are also limited to 100 sq. in. in 60, 90 and 180 minute temperature rise doors. Polished wire glass, specialty tempered glass, specialty fire protective glass and ceramics fall into this category.

Meanwhile, fire-resistive glazings, tested to ASTM E-119/UL 263 and typically rated 60 minutes and above, also help contain fire and smoke in an area, as well as protect people on the other side of the glass from the flame’s radiant heat. As a result, they are not subjected to the same size limitation as fire-protective glasses. The ASTM E-119/UL 263 standard for fire-resistive glazings is designed to maintain a temperature not exceeding 250°F above ambient on the non-fire side of the glass. This is to prevent the spontaneous combustion of materials like paper and drapings due to the fire’s radiant heat.

Fire-resistive glazings incorporate a semi-rigid intumescent interlayer (SRIIL) that is activated during a fire. It swells and turns opaque when heated, thus creating a barrier that radiant heat, smoke and flames cannot pass through.

Required Tests for Fire-Rated Glass

Before they can be certified as fire-rated, these materials need to undergo a rigorous series of tests to ensure that they are up to the standard of fire and life safety codes. Here are some of the tests that fire-rated glazings are subjected to:

-

Fire Test

To ensure that the fire-rated glass can contain fire and smoke and remain intact when exposed to intense heat, it must undergo and pass a fire endurance test that simulates an actual structural fire situation.

In the fire test, the glass and the frame supporting it are heated to a high temperature up to 1800°F in a large test furnace for a specific duration. The laboratory then assigns a rating ranging from 20 minutes to 180 minutes, depending on how long the assembly could withstand the fire. During the test, the assembly must retain its structural integrity and show no signs of breaking or flaming.

-

Hose Stream Test

Immediately after the fire test, the laboratory will spray a fire hose directly at the assembly to test its integrity after a fire. The glass must withstand the impact from the spray of the fire hose and the extreme change in temperature.

During the test, water is supplied from a hose that is 20 feet away. The water pressure is set at a force of 30 psi. If the glass remains intact or the openings are within the standard, it will pass the hose stream test. Note that NFPA 257 (Fire Tests of Window Assemblies) hose stream test allows for a 30% loss of glazing around the perimeter and a 5% loss at the center.

-

Impact Safety Test

For some applications, the glass must pass an impact safety test to determine if the glass will break and shatter into sharp and dangerous shards.

A weighted ball is swung from various heights during the impact safety test to strike against the glass. The U.S. CPSC (Consumer Products Safety Commission) categorizes the glasses based on their performance.

Glazing under Category I can withstand a 150 ft/lb of impact, representing the impact of a small child running into the glass. This test is simulated by having the weighted ball swung by 18 inches. Meanwhile, glazing under Category II can withstand a 400 ft/lb impact, representing the impact of a fully grown man into the glass. Instead of an 18-inch drop, this test utilizes a 48-inch drop for simulation.

-

Radiant Heat Test

Apart from the flames and smoke, one of the silent killers in building fires is the radiant heat from the fire. Radiant heat can cause unbearable human pain at 5 kilowatts per square meter. Also, if the heat gets high enough, flammable materials like clothes and wood can combust even if the fire does not touch them.

In the radiant heat test, the fire-rated glass assembly is heated at one side to a high temperature reaching 1800°F. If the temperature of the non-fire side of the glass does not rise by 250°F above the ambient temperature (in accordance to ASTM E-119/NFPA 251/UL 263), then the fire-rated glass assembly will pass the test.

Key Takeaway

Structural fires can happen at the most inopportune moment, which is why your building must be equipped with the latest technology to save as many lives as possible. One of the best ways to achieve that is by incorporating fire-rated glass in your projects. Not only is it functional, but it is also aesthetically pleasing.

If you are looking for a supplier of fire-rated glass for your next project, check out our wide array of products at SAFTI FIRST. We are the industry leader in USA-made fire-rated glass and framing products that are durable and flexible and can fit any construction project.