All you should know about Fire-Resistant Glazing

ASTM E119/UL 263 Compliance Transforms the Range of Glazing Applications

|

| Fire and Hurricane Rated Curtain Wall at Orlando V.A. Medical Center in Lake Nona, Fla. | Photo courtesy of SAFTI FIRST |

What You Should Know About Fire-Resistant Glazing

The march of innovation in the built environment is relentless. Think of the advances in concrete, aluminum, steel, masonry, wood, gypsum, plastic, and MEP systems over the last 20 years and the IBC’s ever-evolving response to them. You can count on code to keep pace with the life-safety measures required to best serve the public interest.

This edition of Code Counts examines innovations in fire-rated glazing. You may know, for example, the 2018 IBC distinguishes two fire-rated categories fire-protective and fire-resistant glazing. How does the 2018 IBC define the two? How can you tell if the glazing panel you’re reviewing complies with code for the application it’s intended for? How do IBC requirements help usher in a new dimension to design freedom, structural transparency, multi-function versatility, and life-safety protection?

A Tale of Two Definitions

The 2012 IBC transformed how code officials viewed fire-rated glazing. The 2012 IBC for the first time defined the distinction between fire protection and fire resistance. The code now recognizes the fundamental differences between the two rating distinctions. According to the 2018 IBC Section 202, a fire protection rating is defined as “The period of time that an opening protective will maintain the ability to confine a fire as determined by test specified in Section 716. Ratings are stated in hours or minutes.” Fire resistance is defined in Section 202 as “That property of materials or their assemblies that prevents or retards the passage of excessive heat, hot gases or flames under conditions of use.”

Underscore those words “… excessive heat, hot gases …” in the above definition. Fire protective glazing is engineered to block the visual elements of fire, namely the flames and smoke, through the rating period, such as 20 minutes. It compartmentalizes smoke and flames.

Fire resistance takes that barrier capability to a new level. A fire resistance rating signifies the glazing not only blocks flame and smoke but also “excessive heat, hot gases” which aren’t visible but can pose an extreme threat to life-safety.

“Code officials have an outstanding understanding of the IBC. The issue today is glazing can now function as an ASTM E119/UL 263 compliant barrier wall, not just a window or storefront curtain wall,” observes Tim Nass, vice president of sales for SAFTI FIRST, a leading glazing manufacturer. “Fire-resistant glazing is transparent. So when a transparent material is specified for a 120-minute application, including blocking radiant heat, it’s understandable why it might raise questions with the code official.”

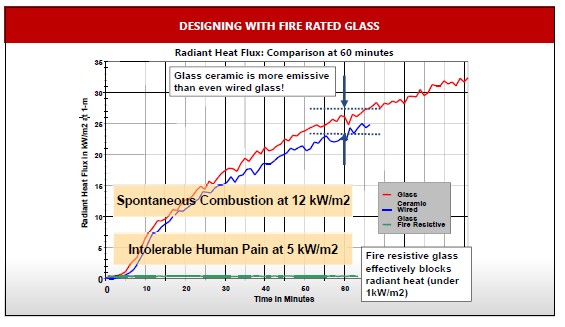

This chart illustrates the extreme differences between fire protective- and fire resistant-rated glazing as it relates to radiant heat transmission. Glazing rated as fire resistant-rated offers building occupants a passive life-safety shield that can be counted on to continuously perform even after the unlikely but possible failure of an active fire suppression system.

More Fire-Resistant Glazing Applications

For architects and building owners and developers faced with implementing an alternate assembly using special purpose deluge sprinkler systems with fixed glazing assemblies in 1-2 hour fire resistive applications, an ASTM E119/UL 263-compliant glazing solution is welcome news. The alternative sprinkler-based approach, subject to AHJ approval, can include a wide range of time-consuming and costly considerations:

- • Preparing documented proof that the design and installation requirements are met

- • Hydraulic calculations for each installation

- • Ensuring an automatic, dedicated water supply capable of supplying 1 or 2 hours of water, depending on application requirements

- • Upgrading pumps and pipes to ensure prescribed water pressure for each installation

- • Ongoing sprinkler system maintenance

Not to mention that sprinklers can, and do, fail. As the National Fire Protection Association (NFPA) has reported, sprinklers operate effectively only 87 percent of the time. The NFPA reported the majority of sprinkler failures occurred because the system was shut off, water from the system failed to reach the fire, or not enough water was released. These failures could be caused by a number of factors, including manual tampering, lack of maintenance, low water pressure, or damage to the system a real possibility during natural disasters such as earthquakes. When the sprinkler system fails to operate, the non-rated fixed glazing assemblies, in turn, fail to compartmentalize smoke, flames and radiant heat. Safe egress is often impossible.

|

| A fire-rated glass stairwell | Photo: SAFTI FIRST |

The specification of an ASTM E119/UL 263 glazing solution presents the architect with reliable, 24/7 protection without the need for mechanical triggers. A fire-resistant glazing solution also expands the design possibilities for 2-hour fire rating applications, such as stairwells, elevator enclosures, and curtain walls.

|

| 21c Museum Hotel in Nashville, Tenn features a 1-hour fire resistive glazed floor system | Courtesy of SAFTI FIRST | Photo: Mike Schwartz |

Opening up the structure to even more natural light creates an aesthetic that’s increasingly popular with building owners, developers, and tenants. Code officials should anticipate more structures incorporating fire-resistant glazing in areas once thought of as off-limits to transparent design materials. “I frequently present to code officials,” Nass says. “They always ask the right questions. They want to be certain about testing and compliance. They never want to put anyone in danger.”

How to Identify a Fire-Resistant Glazing Product

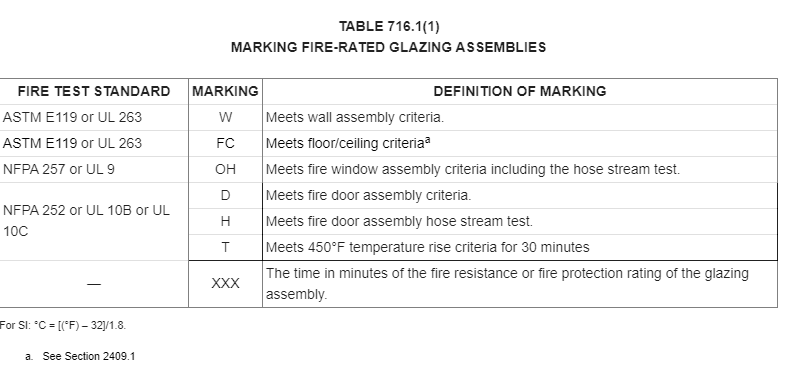

To assist code officials in determining if a glazing product meets 2018 IBC standards, code officials are encouraged to review Table 716.1(1), Marking Fire-Rated Glazing Assemblies:

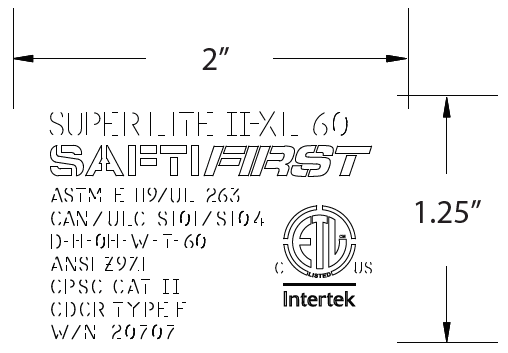

Effective with the 2012 IBC, glazing manufacturers are required to stencil onto the glazing product itself the testing standards the products has passed from a nationally recognized testing laboratory (NRTL). The stencil features the marking code noted in Table 716.1(1) and appears similar to this sample in a 2” x 1.25” format:

Special Fire-Resistant Glazing Applications

|

| Fire-resistant glass with security glazing forms single assembly protection against fire, bullets, blast, and forced entry | Photo courtesy of SAFTI FIRST |

Fire-resistant glazing may also be customized to broaden its application across a variety of security and environmental applications. Fire-resistant glass can also be combined with security glazing to form a single assembly that protects against fire, bullets, blast, and forced entry. For architects and building owners, the multi-function capability simplifies specification. For code officials, single-source responsibility and manufacturing help testing and listing verification.

Fire-resistant glazing can also be manufactured to meet hurricane code standards, including Florida and Texas Product Approval Numbers, and UL certifications.

Notable examples of the fire-resistant glazing in action include the $211 million Weed Army Community Hospital in Fort Irwin, Calif., the $600 million Orlando V.A. Medical Center in Lake Nona, Fla., and the $330 million San Jose Regional Medical Center in San Jose, Calif.

Learn More

To learn more about fire-rated glazing and framing components, review the 2018 IBC, especially Chapter 7 – Fire and Smoke Protection Features. Comprehensive product information including datasheets, Health Product Declarations, and the ICC-registered continuing professional education program, Designing with Fire Rated Glass (.10 ICC CEU), is available at the SAFTI FIRST website.