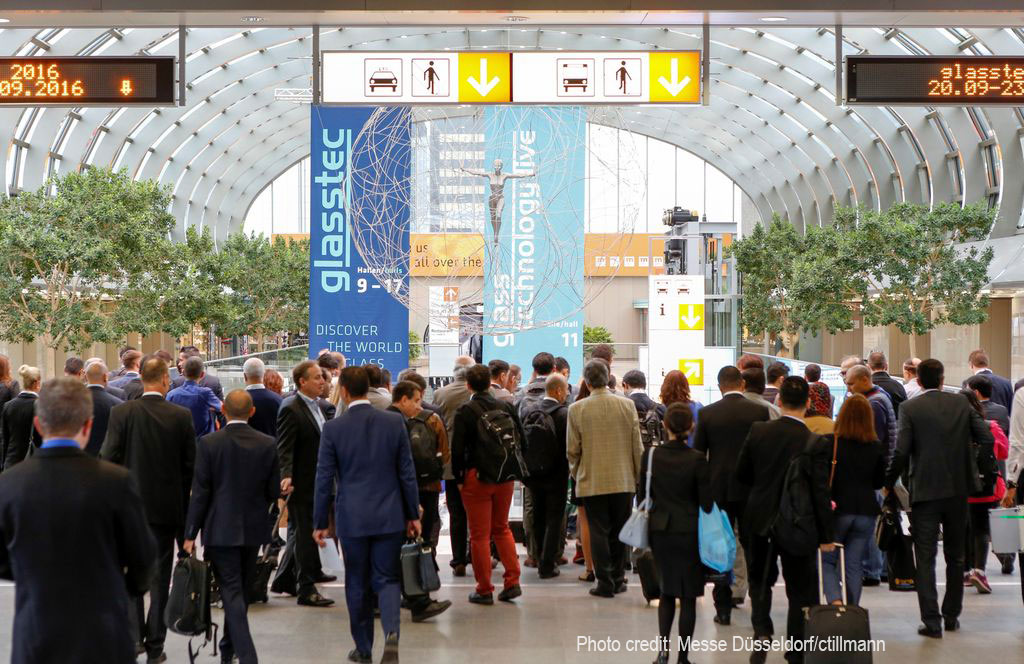

International glazing community celebrates innovation at the Glasstec show in Dusseldorf

International glazing community celebrates innovation at the Glasstec show in Dusseldorf, 2016

The recently concluded Glasstec tradeshow in Dusseldorf, Germany is an event that I look forward to attending every 2 years. With 9 exhibition halls showcasing over 1,235 exhibitors from 52 countries and with over 40,000 visitors from 100 countries walking the show, it is still regarded as the leading international trade fair for the glass industry. Indeed, this is where top executives meet to see the latest innovations in glass production & processing, machinery and products.

At the show, it was clear that energy conservation and indoor occupant comfort is a growing trend. With energy costs on the rise, using dynamic glass in the building envelope for energy savings is popular all over Europe, and it is making its way to the US. Various companies were displaying building-integrated photovoltaic glass products that can harvest direct sunlight and convert it to energy. Using electrochromic glass that enables glass to go from clear to opaque as a strategy to control heat and glare is also on the rise. Manufacturers are also developing advanced coatings that are incorporated into the glass to control heat and glare.

We also saw glass products that addressed privacy and security. Manufacturers displayed electric privacy glass using liquid crystal technology to transform glass from transparent to opaque with a flick of a switch. This is popular in both residential and commercial applications where vision and privacy are needed in the same space but at different times (click here for an example). In terms of security, we saw advanced glazing products that appear to look like regular glass but are actually designed to protect against bullets, blast, forced entry or any type of attack. With security and safety being a rising concern in government buildings here and abroad, we see this as a growing market. Even high-profile commercial buildings are incorporating security glass in case an attack happens.

On the decorative side, LEDs (light-emitting diodes) embedded in the glass transforms glass from a building product to a blank canvas for creativity. While vision and transparency is still the primary function of glazing, it can become a giant screen and interactive medium to display high impact visuals.

The good news is that with all the new and innovative products that I saw at the Glasstec show, there is nothing that cannot be incorporated in the fire rated glass systems that we manufacture today. It was actually at this how, almost 38 years ago, where I first saw this new type of clear glass that was able to resist fire. This technology did not exist in the US at that time, and I can see how a product like this can change how buildings are designed in the US. Wired glass used to be the only fire rated glass option, and it had a lot of size and application limitations. This new type of fire rated glass was optically clear without any embedded wires and outperformed wired glass in both fire and impact safety which meant it can be used in sizes, applications and ratings like never before. I brought this product to the US in 1978 and developed a fire resistive framing system (GPX GlassProtex) to be used alongside it in 1984. Having a complete glass and framing system paved the way for full-lite 60-90 minute doors, fire resistive storefronts and curtain walls up to 2 hours, and much more. By 1998, we started US manufacturing of SuperLite II-XL, the first fire resistive glass product made in the USA.

In the last two decades, we have seen an increase in specialty fire rated applications, where in addition to protecting against fire, the system was also designed to simultaneously protect against hurricanes, blast, bullets, forced entry, UV and noise. Today, our fire rated systems are also available in various architectural and decorative make-ups, transparent butt-glazed systems and even fire resistive floors. These fire rated glass and framing systems are produced in our manufacturing facility in Merced, CA, making us the first and only vertically-integrated, single-source fire rated glass and framing manufacturer in the US.

All this innovation is driven largely in part by you the architectural community. As designers continue to push the envelope on what glass can do, manufacturers such as ourselves will continue to provide innovative solutions that transform vision to reality. The next Glasstec show is scheduled on October 23-28, 2018 in Dusseldorf, Germany perhaps we will see you there!