Using Sprinklers as an Alternate to 1-2 Hour Fire Resistive Glazing

Before considering and alternate assembly that requires prior AHJ approval, read below.

Glazing that meets the ASTM E-119 standard are classified as “fire resistive” or “fire-resistance-rated” in Chapter 7 of the IBC. Marked with a “W”, it can be used as fire barriers in exit enclosures, exit passageways or horizontal exits to ensure that building occupants are protected from smoke, flames and dangerous radiant heat as they exit a burning building. In cases where evacuation is difficult or impossible (ex. immobile patients in hospitals or long-term care facilities), the fire barriers in exit enclosures, exit passageways or horizontal exits serve as areas of safe haven where building occupants can await rescue.

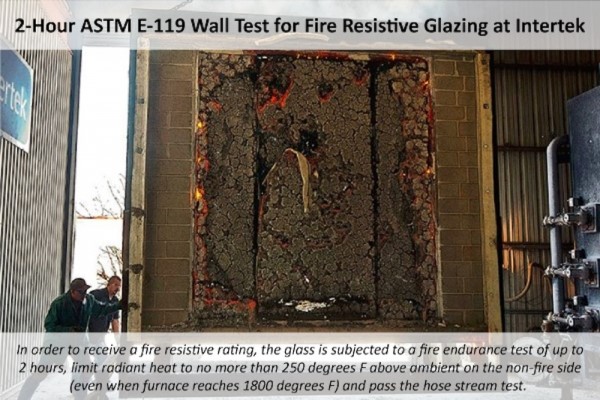

Given this important life safety function, the ASTM E-119 test is the most stringent and most difficult test to pass for all fire rated glazing assemblies – and rightfully so. The test specimen has to withstand temperatures of over 1800 degrees F without the passage of flame or gases hot enough to ignite cotton waste for the entire duration of the test; has to pass prescribed hose stream test; and has to limit the temperature rise on the non-fire side to less than 250 degrees F over ambient.

So it surprising that a modified, less stringent version of the ASTM E-119 test now applies to special-purpose sprinklers used with fixed glazed assemblies as an alternative product for 1-2 hour fire resistive wall assemblies. Other than following the time and temperature curve, there is nothing that resembles the original ASTM E-119 test. There is no cotton waste test, there is no hose stream test, and there is no documented report showing how it limits the temperature rise on the non-fire side to less than 250 degrees F over ambient.

TYCO, a sprinkler manufacturer and proponent of the modified criteria, has capitalized on this sell its TYCO Model WS sprinkler system with heat strengthened or tempered glass as an alternative product in 1-2 hour fire resistive walls through ESR-2397. TGP, distributor of fire protective ceramics, has jumped in with TYCO to sell laminated ceramic with TYCO Model WS sprinklers as an alternative to 1-2 hour fire resistive walls.

In order to use the wetted-glass approach that TYCO and TGP are pushing, the architect must assume all the work and related costs for submitting the required documentation necessary for the AHJ to evaluate the TYCO Model WS and FireLite Plus WS as alternative products to ASTM E-119 rated fire resistive glazing. But before the architect or AHJ considers this alternative system, there are some important concerns that must be raised:

Documented Sprinkler Failure

The potential effectiveness of the TYCO Model WS and FireLite Plus WS systems is entirely dependent on 100% sprinkler reliability and effectiveness, which doesn’t exist. As the National Fire Protection Association (NFPA) has reported, sprinklers operated effectively only 87% of the time. In the same NFPA report, majority of sprinkler failures occurred because the system was shut off, and that majority of sprinkler ineffectiveness was because water did not reach the fire or not enough water was released. This could be caused by a number of factors, including manual tampering, lack of maintenance, low water pressure or damage to the system, which is a real possibility during natural disasters such as earthquakes.

Given this difference, how can an alternative ‘wall’ system that is entirely dependent on 100% sprinkler reliability – which does not exist per the NFPA’s report – be relied upon to provide the same level of protection that fire resistive glazing assemblies provide 24 hours a day, 7 days a week without the mechanical triggers that sprinklers need?

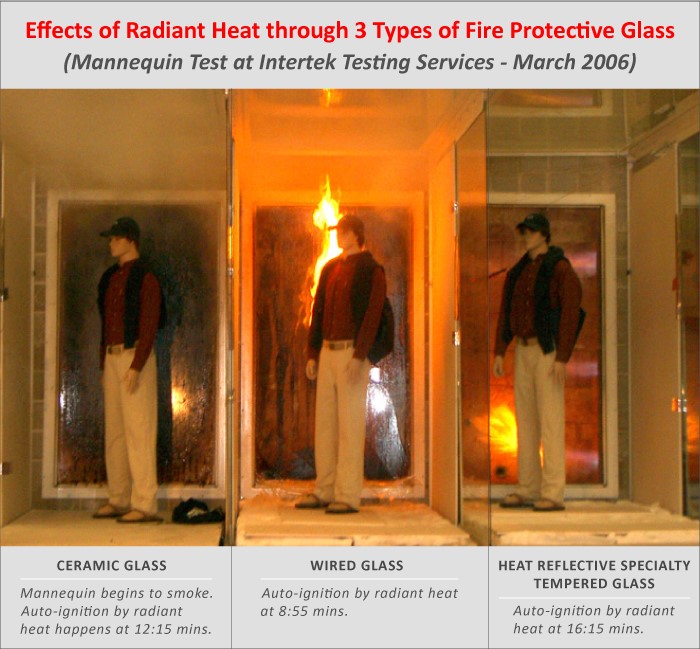

Questionable Radiant Heat Protection

In addition to sprinkler failure, another concern that should be raised is how the TYCO Model WS or FireLite Plus WS system limits radiant heat. Wetting the surface of heat-strengthened or tempered glass may prevent thermal shock and compartmentalize smoke and flames, but there is no documented evidence of limiting the passage of radiant heat to less than 250 degrees F over ambient. Ceramics may be able to resist cracking or shattering at high temperatures, but the IBC limits its use to fire protective applications only because it does not limit radiant heat whatsoever.

Fact is, the only materials proven to limit the passage of radiant heat to less than 250 degrees F over ambient are fire resistive building materials that have successfully passed ASTM E-119 testing without any modifications to the test method or test assembly.

Allowing an alternative ‘wall’ that relies on sprinklers wetting the surface of heat-strengthened, tempered or ceramic glass to take the place of readily available, true ASTM E-119 tested, listed and labeled fire resistive glazing assembly means the risking the lives of building occupants that the code community serves to protect.

Cost Concerns

Somehow, there is a perception that the higher prices of fire resistive glazing compared to non-rated glazing is enough to consider TYCO Model WS and FireLite Plus WS as cost-effective alternatives. However, these alternative assembly uses a special wet-pipe sprinkler system that is different from the sprinklers used throughout the building. Per ESR-2397, the automatic water supply must have the capability of supplying 1 or 2 hours of water, depending on the rating of the wall. Depending on the circumstances, this can require larger pumps, increased water pressure and additional water that dramatically increases the initial cost of installing the system (more so if FireLite Plus is used, which is already expensive) and the perpetual maintenance costs required to make sure that the sprinkler system works.

This alternative ‘wall’ system could cost hundreds of thousands and dollars more over time compared to USA-made, competitively prices fire resistive glazing products that don’t need special wet-pipe sprinklers, has no maintenance costs and are potentially 20-50% cheaper than laminated ceramic.

Design Restrictions

Looking at ESR-2397 more closely shows several restrictions on the TYCO Model WS and FirePlus WS systems, including:

- Maximum exposed glazing height of 13 feet. No horizontal mullions allowed.

- 36” minimum pony wall required with heat-strengthened or tempered glazing.

- 36” pony wall requirement waived when using FireLite Plus, its sheet size is restricted to 96”. With most floors having a typical height of 10 feet (120”), floor-to-ceiling glazing cannot be achieved without at least 2 feet (24”) of opaque wall.

- Visible amber tint typical of all ceramics when using FireLite Plus WS.

- Cannot be used in exterior wall applications where the fire separation distance is less than 10 feet for states following the 2009, 2012 and 2015 IBC (5 feet for states following the 2006 IBC).

None of these restrictions apply to 1-2 hour fire resistive glazing assemblies. Architects can have floor-to-ceiling, wall-to-wall glazing free from amber tints. Butt-glazed wall assemblies are also available for maximum transparency.

Of course, it is still up to the architect to decide if it is worth going through the alternative approval process for the TYCO Model WS or FireLite Plus WS products. At the same time, the AHJ still has the authority to either approve or reject these products based on IBC sections 104.10 and 104.1. What I hope to have accomplished through this blog is provide architects and AHJs with thoughtful pause on what fire resistive assemblies tested to ASTM E119 (without modifications to the test method or assembly) are supposed to do – 100% of the time, without failure. It’s a matter of life safety and occupant protection, after all.