2003 IBC Sec 715 Opening Protectives

IBC Sec 715 Opening Protectives

2003 IBC Sec 715 Opening Protectives. The text of the 2003 IBC, International Business Code, Section 715 related to window openings and the use of fire rated glass.

2003 IBC Sec 715 Opening Protectives

Source: International Building Code, 2003

715.1 – 4.9

715.1 General. Opening required by other sections of this code shall comply with the provisions of the section.

715.2 Fire-resistance-rated glazing. Labeled fire-resistance-rated glazing tested as part of a fire-resistance-rated wall assembly in accordance with ASTME 119 shall not be required to comply with this section.

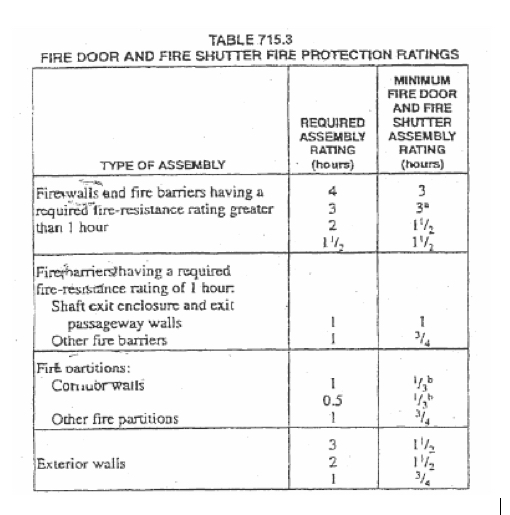

715.3 Fire door and shutter assemblies. Approved fire door and fire shutter assemblies shall be constructed of any material or assembly of component materials that conforms to the test requirements of Section 715.3.1, 715.3.2 or 715.3.3 and the fire protection rating indicated in Table 715.3. Fire door assemblies and shutters shall be installed in accordance with provisions of this section and NFPA 80.

|

Exceptions:

- Labeled protective assemblies that conform to the requirements of this section or UL 10A, UL 14B and UL 14C for tin-clad fire door assemblies.

- Floor fire doors shall comply with Section 712.4.6.

A. Two doors, each with a fire protection rating of 1 1/2 hours, installed on opposite sides of the same opening in a fire wall, shall be deemed equivalent in fire protection rating to one 3-hour fire door.

B. For testing requirements, see Section 715.3.3

715.3.1 Side-hinged or pivoted swinging doors. Side hinged and pivoted swinging doors shall be tested in accordance with NFPA 252 or UL 10C. After 5 minutes into the NFPA 252 test, the neutral pressure level in the furnace shall be established at 40 inches (1016 mm) or less above the sill.

715.3.2 Other types of doors. Other types of doors. Other types of doors, including swinging elevator doors, shall be tested in accordance with NFPA 252 or UL 10B. The pressure in the furnace shall be maintained as nearly equal to the atmospheric pressure as possible. Once established; the pressure shall be maintained during the entire test period.

715.3.3 Door assemblies in corridors and smoke barriers. Fire door assemblies required to have a minimum fire protection rating of 20 minutes where located in corridor walls or smoke barrier walls having a fire-resistance rating in accordance with Table 715.3 shall be tested in accordance with NFPA 252 or UL 10C without the hose stream test. If a 20-minute fire door assembly contains glazing material, the glazing material in the door itself shall have a minimum fire protection rating 20 minutes and exempt from the hose stream test. Glazing material in any other part of the door assembly, including transom lites and sidelines shall be tested in accordance with NFPA 257, including the hose stream test,i n accordance with 715.4 . Fire door assemblies shall also meet the requirements for a smoke-draft-control door assembly tested in accordance with UL 1784 with an artificial bottom seal installed across the full width of the bottom of the door assembly. The air leakage rate of the door assembly shall not exceed 3.0 cfm per square foot (0.01524 m³/slm²) of door opening at 0.10 inch (24.9 Pa) of water for both the ambient temperature and elevated temperature tests. Louvers shall be prohibited.

Exceptions:

- Viewports that require a hole not larger than 1 inch (25 min) in diameter through the door, have a least an 0.25-inch-thick (6.4 mm) glass dise and the holder is of metal that will not melt out where subject to temperature of 1.700°F (927°C) Corridor door assemblies in occupancies of Group 1-2 shall be in accordance with Section 407.3.1

- Corridor door assemblies in occupancies of Group I-2 shall be in accordance with section 407.3.1

- Unprotected openings shall be permitted for corridors in multitheater complexes where each motion picture auditorium has at least one-half of its required exit or exit access doorways opening directly to the exterior or into an exit passageway.

715.3.4 Doors in vertical exit enclosures and exit passageways. Fire door assemblies in vertical exit enclosures and exit passageways shall have a maximum transmitted temperature end point of not more than 450°F (232°C) above ambient at the end of 30 minutes of standard fire test exposure.

Exception: The maximum transmitted temperature end point is not required in buildings equipped throughout with an automatic sprinkler system installed in accordance with Section 903.1.1 or 903.3.1.2

715.3.4.1 Glazing in door. Fire-protection-rated glazing in excess of 100 square inches (0.0065 m²) shall be permitted in fire door assemblies when tested in accordance with NFPA 252 as components of the door assemblies and not as glass lights, and shall have a maximum transmits temperature end point of 450°F (232°C) in accordance with Section 715.3.4

Exception: The maximum transmitted temperature end point is not required in buildings equipped throughout with an automatic sprinkler system installed in accordance with Section 903.3.1.1 or 903.3.1.2.

715.3.5 Labeled protective assemblies. Fire door assemblies shall bee labeled by an approved agency. The labels shall comply with NFPA 80, and shall be permanently affixed to the door of frame.

715.3.5.1 Fire door labeling requirements. Fire doors shall be labeled showing the name of the manufacturer, the name of the third-party inspection agency, the fire protection rating and, where required for fire doors in exit enclosures by Section 715.3.4, the maximum transmitted temperature end point. Smoke and draft control doors complying with UL 1784 shall be labeled as such. Labels shall be approved and permanently affixed. The label shall be applied at the factory or location where fabrication and assembly are performed.

715.3.5.2 Oversized doors. Oversized fire doors shall bear an oversized fire door label by an approved agency or shall be provided with a certificate of inspection furnished by an approved testing agency. When a certificate of inspection is furnished by an approved testing agency the certificate shall state that the door conforms to the requirements of design, materials, and construction, but has not been subjected to the fire test.

715.3.5.3 Smoke and draft control door labeling requirements. Smoke and draft control doors complying with UL 1784 shall be labeled in accordance with Section 715.3.5.1 and shall show letter “S” on the fire rating label of the door. This marking shall indicate that the door and frame assembly are in compliance when listed or labeled gasketing is also installed.

715.3.5.4 Fire door frame labeling requirements. Fire door frames shall be labeled showing the names of the manufacturer and the third-party inspection agency.

715.3.6 Glazing material. Fire-protection-rated glazing conforming to the opening protection requirements in Section 715.3 shall be permitted in fire door assemblies.

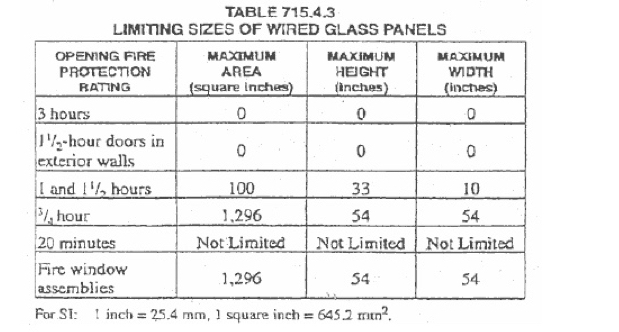

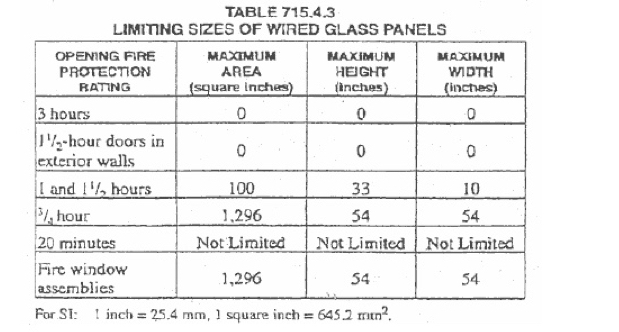

715.3.6.1 Size limitations. Wired glass used in fire doors shall comply with Table 715.4.3. Other fire-protection-rated glazing shall comply with the size limitations of NFPA 80.

Exceptions:

- Fire-protection-rated glazing in fire doors located in fire walls shall be prohibited except that where serving as a horizontal exit, a self-closing swinging door shall be permitted to have a vision panel of not more than 100 square inches (0.065 m²) without a dimension exceeding 10 inches (254 mm).

- Fire-protection-rated glazing shall not be installed in fire doors having a 1½-hour fire protection rating intended for installation in fire barriers, unless the glazing is not more than 100 square inches (0.065 m²) in area.

715.3.6.2 Exit and elevator protectives. Approved fire-protection-rated glazing used in fire doors in elevator and stairway shaft enclosures shall be so located as to furnish clear vision of the passageway or approach to the elevator or stairway.

705.3.6.3 Labeling. Fire protection-rated glazing shall bear a label or other identification showing the name of the manufacturer, the test standard and the fire protection rating. Such label or other identification shall be issued by an approved agency and shall be permanently affixed.

715.3.6.4 Safety Glazing. Fire-protection-rated glazing installed in fire doors or fire window assemblies in areas subject to human impact in hazardous locations shall comply with Chapter 24

715.3.7 Door closing. Fire doors shall be self-closing or automatic-closing in accordance with this section.

Exception: Fire doors located in common walls separating sleeping units in Group R-1 shall be permitted without automatic-closing or self-closing devices.

715.3.7.1 Latch required. Unless otherwise specifically permitted, single fire doors and both leaves of pairs of side-hinged swinging fire doors shall be provided with an active latch bolt that will secure the door when it is closed.

715.3.7.2 Automatic-closing fire door assemblies. Automatic-closing fire door assemblies shall be self-closing in accordance with NFPA 80.

715.3.7.3 Smoke-activated doors. Automatic-closing fire doors installed in the following locations shall be automatic-closing by the actuation of smoke detectors installed in accordance with Section 907.10 or by loss of power to the smoke detector or hold-open device. Fire doors that are automatic-closing by smoke detection shall not have more than 10-second delay before the door starts to close after the smoke detector is actuated.

- Doors installed across a corridor

- Doors that protect openings in horizontal exists, exits or exit access corridors required to be of fire-resistance-rated construction.

- Doors that protect openings in walls required to be fire-resistance rated by Table 302.1.1.

- Doors installed in smoke barriers in accordance with section 709.5.

- Doors installed in fire partitions in accordance with section 708.6.

- Doors installed in a fire wall in accordance with 705.8.

715.3.7.4. Doors in pedestrian ways. Vertical sliding or vertical rolling steel fire doors in openings through which pedestrians travel shall be heat activated or activated by smoke detectors with alarm verification.

715.3.8 Swinging fire shutters. Where fire shutters. Where fire shutters of the swinging type are installed in exterior openings, not less than one row in every three vertical rows shall be arranged to be readily opened from the outside, and shall be identified by distinguishing marks or letters not less than 6 inches (152mm) high.

715.3.9 Rolling fire shutters. Where fire shutters of the rolling type are installed, such shutters shall include approved automatic-closing devices.

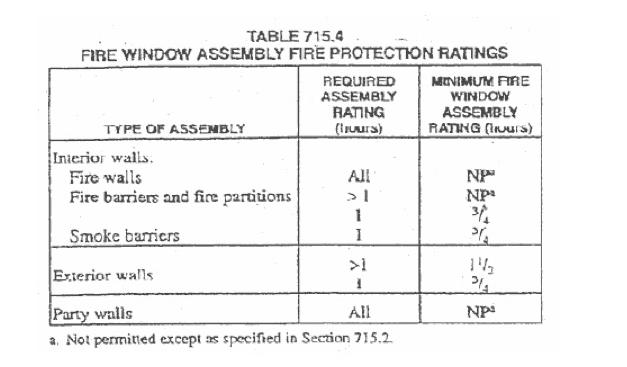

715.4 Fire-protection rated glazing. Glazing in fire window assemblies shall be fire protection rated in accordance with this section and Table 715.4. Glazing in fire doors shall comply with Section 715.3.6. Fire-protection-rated glazing installed as an opening protective in fire partitions, smoke barriers and fire barriers shall be tested in accordance with and shall meet the acceptance criteria of NFPA 257 for a fire protection rating of 45 minutes. Fire-protection-rated glazing shall also comply with NFPA 80. Fire-protection-rated glazing required in accordance with Section 704.12 for exterior wall opening protection shall be tested in accordance with and shall meet the acceptance criteria of NFPA 257 for a fire protection rating as required in Section 715.4.7.

|

Exceptions:

- Wire glass in accordance with Section 715.4.3.

- Fire-protection-rated glazing in 0.5-hour fire-resistance-rated partitions is permitted to have an 0.33-hour fire protection rating.

715.4.1 Testing under positive pressure. NFPA 257 shall evaluate fire-protection-rated glazing under positive pressure. Within the first 10 minutes of a test, the pressure in the furnace shall be adjusted so at least two-thirds of the test specimen is above the neutral pressure plane, and the neutral pressure plane shall be maintained at that height for the balance of the test.

715.4.2 Nonsymmetrical glazing systems. Nonsymmetrical fire-protection-rated glazing system in fire partitions, fire barriers or in exterior walls with a fire separation of 5 feet (1524 mm) or less pursuant to Section 704 shall be tested both faces exposed to the furnace, and the assigned fire protection rating shall be the shortest duration obtained from the two tests conducted in compliance with NFPA 257.

715.4.3 Wired glass. Steel window frame assemblies of 0.1215-inch (3.2 mm) minimum solid section or of not less than nominal 0.048-inch-thick (1.2 mm) formed sheet steel members fabricated by pressing, mitering, riveting, interlocking or welding and having provision for glazing with ¼-inch (6.4 mm) wired glass where securely installed in the building construction and glazed with ¼-inch (6.4 mm) labeled wired glass shall be deemed to meet the requirements for a ¾-hour fire window assembly. Wired glass panels shall conform to the size limitations set forth in Table 715.4.3.

|

715.4.4 Nonwired glass. Glazing other than wired glass in fire window assemblies shall be fire-protection-rated glazing installed in accordance with and complying with the size limitations set forth in NFPA 80.

715.4.5 Installation. Fire-protection-rated glazing shall be in the fixed position or be automatic-closing and shall be installed in approved frames.

715.4.6 Window mullions. Metal mullions that exceed a nominal height of 12 feet (3658 mm) shall be protected with materials to afford the same fire-resistance rating as required for the wall a maximum fire-resistance rating of 1 hour in accordance with this section.

715.4.7.1 Where permitted. Fire-protection-rated glazing shall be limited to fire partitions designed in accordance with Section 708 and fire barriers utilized in the applications set forth in Sections 706.3.5 and 706.3.6 where the fire-resistance rating does not exceed 1 hour.

715.4.7.2 Size limitations. The total area of windows shall not exceed 25 percent of the area of a common wall with any room.

715.4.8 Exterior fire window assemblies. Exterior openings, other than doors, required to be protected by Section 704.12, where located in a wall required by Table 602 to have a fire-resistance rating greater than 1 hour, shall be protected with an assembly having a fire protection rating of not less than 1½ hours. Exterior openings required to be protected by Section 704.8, where located in a wall required by Table 602 to have a fire-resistance rating of 1 hour, shall be protected with an assembly having a fire protection rating of not less than ¾ hour. Exterior openings required to be protected by Section 704.9 or 704.10 shall be protected with an assembly having a fire protection in accordance with Section 704.8, 704.9 or 704.10 shall have a fire protection rating of not less than ¾ hour.

715.4.9 Labeling requirements. Fire-protection-rated glazing shall bear a label or other identification showing the name of the manufacturer, the rest standard, and the fire protection rating. Such label or identification shall be issued by an approved agency and shall be permanently affixed.