Architects’ Guide to Fire Rated Glass 2013 | Article

Architects’ Guide to Fire Rated Glass 2013

Architects’ Guide to Fire Rated Glass 2013. This Architects’ Guide first appeared in USGlass magazine to provide guidance on interior and exterior applications of fire rated glass in all sizes and types.

When, Where, Why? Architects’ Guide to Fire Rated Glass

by Ellen Rogers

|

Fire rated glass has come a long way since the days when the only fire-rated possibility was wired glass in hallways and stairwells. From clear glass, to increasingly larger sizes to combining glazing features and benefits, fire-rated glazing not only provides a safe environment, but can also enhance the building’s aesthetics. Still, many architects are unaware of this product evolution.

Further, building codes and testing requirements are also changing rapidly. As a result, architects may be faced pondering which product to use, when and where. The answers aren’t always clear. However, as design and construction opportunities for fire-rated glass continue to grow, understanding the products as well as when and where to use them can help save re-design—or even re-installation—headaches in the end.

Where to Use it

Fire rated glass products have evolved tremendously over the past two decades. Architects, designers and specifiers have a wide range of product choices for applications beyond just hallways and stairwells. While product manufacturers say interior applications still remain the primary area for use, new developments allow for increasingly open, transparent designs.

Peter Lindgren, president of Aluflam USA in Huntington Beach, Calif., says much of the work in which his company is involved includes institutional projects, schools, hospitals and universities.

“We also do work on commercial buildings, corporate headquarters, hotels and banks. We do very little private residential, though we do get the occasional order where someone wants fire-rated glazing between the home and garage,” says Lindgren, explaining such projects are typically within the very high-end market and the percentage of such jobs is small.

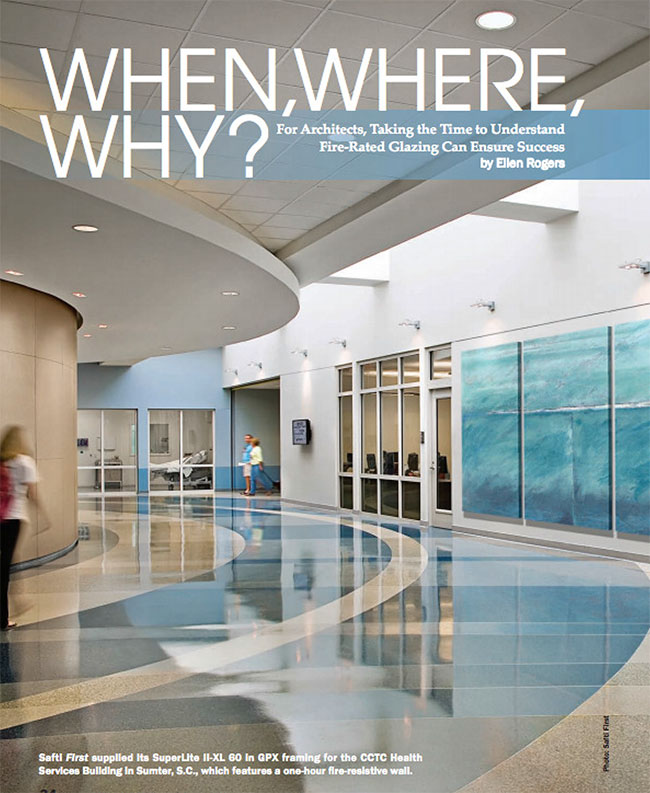

Diana San Diego, marketing director with San Francisco-based Safti First, adds that while fire-rated products are typically installed near exits, exit passageways, stairwells and corridors to provide safe egress for people, they’re also seeing an increasing interest in exterior settings.

“Fire-rated glazing products can be used in exteriors for property line applications, in urban locations or areas prone to wildfire and also places that are adjacent to parking lots,” says San Diego. “We’re getting more and more requests for fire-rated products for use in exteriors.” She explains this is due to the close proximity of property lines, for instance, “especially in areas where they are building pretty much at the property lines.”

Christian Mueller, general manager of Vetrotech Saint-Gobain (VSG) in Auburn, Wash., adds that the key difference in fire-rated glazing products compared to other fire-rated materials is that these are transparent; all fire-rated materials ultimately serve the same purpose.

“The intention is to prevent fire from passing along and affecting other parts of the building and that is the main purpose of any passive fire-rated application,” says Mueller.

The question of “where can I use it?” may seem like one that’s answered easily, but that’s not always the case. San Diego says architects and specifiers often ask what type of products they can use for the applications.

“They may have a need for a one-hour stairwell, so they ask us, ‘what can I use?’” She says one area that causes much of the confusion and misunderstanding is the differences in fire-protective compared to fire-resistive.

“You can have 60-minute fire-resistive and 60-minute fire-protective, but they are not the same,” she says. “Architects need to look at overall performance and what is required for the specific application.”

Fire protective glass is designed to compartmentalize smoke and flames and is subject to application, area and size limitations under the IBC. Fire protective glass is typically used in doors and openings up to 45 minutes and cannot exceed 25 percent of the total wall area because it does not block radiant heat transmission. On the other hand, Fire resistive compartmentalizes smoke and flames, and blocks the transmission of radiant heat through the glazing. (See sidebar below for more details.)

Kevin Frisone, VSG sales and marketing manager, North America, agrees.

“Probably the most discussed [topic] is the two different types, protective and resistive.”

In addition to the protective versus resistive matter, another concern Lindgren points out is understanding the hardware, as he has seen architects specify non-rated products.

“We have to explain that you can’t qualify/maintain the UL listing unless the product is tested as an assembly. It all has to fit within the approved set of requirements,” says Lindgren.

Rated vs. Non-Rated

At first glance a fire-rated product may look much like a non-rated product, but in reality, the two products are very different. “The fact that these products can pass fire testing is a unique ability,” says San Diego, explaining that the longer the rating the more stringent the testing will be.

“With fire-rated walls they are tested to stop smoke, flames and radiant heat,” says San Diego. “Sometimes the fire is so hot the radiant heat is the bigger risk.”

As with any specialty or value-added product, fire-rated glass also comes at a premium. Lindgren says, though, it can be difficult to give an exact estimate as to how much more, but says it could range from about $100 a square-foot more than a non-rated product.

“I sense that since [Aluflam] came to the U.S. about ten years ago there is now a different level of acceptance and understanding from architects as far as the cost of these products. When we first started here it seemed we got a lot of reaction as far as it being expensive,” says Lindgren. “Today it seems they’ve gotten more used to this type of product and are building it in [to the design] early one.”

He continues, “Certainly there can be budget constraints, but … it’s unfortunate to go through the design and specification process and have it turned down. It’s important to build it in from the beginning.”

Framing requirements for fire-rated versus non-rated systems are also different.

“The framing has to stay in the opening so there are tremendous loads on that assembly,” says Lindgren. He says he has seen instances where an architect will design the project with a fire-rated system, but provides details on anchoring as one would with a non-rated product. “Everything needs to be in compliance,” he says.

Know the Codes

“All the provisions for fire-rated products are in Chapter 7 of the IBC and there are three tables that talk about fire-rated door assemblies and windows,” says San Diego. “The references changed with the 2012 code (see box at left).” The 2012 code, for example, distinguishes between fire-resistive and fire-protective.

Framing Functions

Steel is one commonly used material for fire-rated glazing, with aluminum-clad and aluminum systems also available. Lindgren says the all-aluminum option, such as products manufactured by Aluflam, have only been in the U.S. for about ten years. He says his company’s product consists of two extrusions separated by a thermal break and filled with a proprietary material, which provides the fire-rated performance features.

While there are a number of options, and framing can be produced to match the aesthetics and colors of the non-rated materials, San Diego, points out the most important detail in framing is that its rating must match that of the glass.

“If the glass is fire-resistive then the framing must be as well. You have to look at the whole assembly,” she says Mueller agrees.

“The glass and a frame must be tested as unit/system and not individual components,” he says.

Get in Early

Experts agree that one of the best measures architects can take when designing with fire-rated materials is to ask questions early and collaborate with their suppliers.

“When working on these projects it’s always best to consult with the manufacturer early,” says San Diego. “Consulting early can save a lot of headaches. The last thing you want to do is pick the wrong product and have to have it changed. Use the manufacturers as a resource.”

Mueller adds, though, that while the opportunities for architects to use fire-rated glazing materials is growing, education is still needed, as there is a lot of misunderstanding about passive fire-rated materials.

“Some think a sprinkler [which is active] is the cure-all for a potential hazard in a building,” he says. “Both active and passive are important components to building safety. A sprinkler is fire-suppressing not extinguishing.” Mueller says there are those who assume with a sprinkler installed there is then no need for any other protection. “There are lots of passive components that could be neglected.”

That’s why education and communication is critical and manufacturers agree, early involvement and discussions can help create a safe, sound building.

Inset – What’s the Difference?

Experts agree, architects commonly ask questions about the differences in fire-protective glass versus fire-resistive. Here’s a close look at the differences and where each product type can be used.

Fire protective glass is designed to compartmentalize smoke and flames and is subject to application, area and size limitations under the IBC. Fire protective glass is typically used in doors and openings up to 45 minutes and cannot exceed 25 percent of the total wall area because it does not block radiant heat transmission.

Fire resistive glass is not limited in application or size. This type of fire-rated glass compartmentalizes smoke and flames, and blocks the transmission of dangerous levels of radiant heat through the glazing. As a result, it can be used in wall and door applications 60 minutes and above without the size limitations that apply to fire protective glass. Source: Safti First

Inset – New Fire-Rated Glazing ID Codes Approved by ICC

by Kaitlan Mitchell

A code change proposal by the Glazing Industry Code Committees (GICC) (FS84-12) to mandate fire-rated glazing assemblies to be marked in accordance with 716.3, 716.5, and 716.6 identifications was passed in late 2012 by the International Code Council (ICC). It takes effect with the 2015 edition of the International Building Code. The code change affects both non-residential and residential construction covered by the International Building Code, applications that are four or more stories above grade. The GICC code proposal was prompted from the Code Technology Committee’s investigation of the area of study titled “Labeling of Fire-Rated Glazing.”

The code changes were added to clarify Section 716.3, which now includes Section 716.3.1 and 716.3.2 and provides concise requirements for the marking of fire-rated glazing assemblies.

In addition, Section 716.3.1 was moved from Section 716.5.8.3.1. The text was amended to clarify that the provisions of the section also be applicable to fire-rated glazing used in fire door assemblies. To ensure language was consistent with Tables 716.3 and Table 716.5, the text was modified to reflect the fact that fire-rated glazing assemblies that do not meet the temperature or hose stream requirements of this section are not required to be labeled as “NT” and “NH.”

Section 716.3.2 was added to clarify Tables 716.3 and 716.6 are to be used for fire-protection-rated glazing, and to provide details required of the label and standards for performance. For clarification purposes, the language now reflects the same text as presented in Section 715.5.9.1 of the 2009 IBC.

“FS84-12 does several things,” says Carl Baldassarra, P.E., FSFPE, in the Individual Consideration Agenda. “First, it moves the text of section 716.5.8.3.1 to section 716.3.1. Second, in making that move, it deletes “NH” and “NT” as designations used in the marking of fire-rated glazing. Third, it modifies section 716.3.1 and 716.3.2 to clarify that tables 716.3, 716.5 and 716.6 are the primary sources for determining the markings to be used and the relationship of those markings to the various fire-rated glazing applications that are provided for in the code.”

Committee officials state the code change proposal will not increase the cost of construction.

Inset – Table This

What do the codes say about fire-rated glass and what’s most important for architects? Thom Zaremba, code consultant for the Glazing Industry Code Council, provided the following information on the three tables noted in Chapter 7 of the IBC.

Table 716.3. This tells everyone exactly what the [glass] marking system is; the specific fire test standard to which each mark relates; and, lastly, in the definitions it provides, it ties the acceptance criteria of each test standard (or the code in the case of the “temperature rise” criteria) to the marks that are used in the new system. Markings include “W,” which means that the glazing has been tested to the fire wall test standard (ASTM E-119/NFPA 251/UL 263) and thus classified as fire resistive; “D” means the product has been tested to the fire door test standard, NFPA 252; “H” means that it passes the hose stream procedure; “T” means that the glazing meets the temperature rise limits required for doors used in exit enclosures and passageways; and “OH” means that the glazing has been tested to the fire window test standard, NFPA 257, and meets both the fire endurance and hose stream requirements of the test standard.

Table 716.5. This table addresses fire doors and fire shutters, vision panels in fire doors and the transoms and sidelites that are often found in combination with fire doors. This table provides a listing of every different type of opening fire-protective assembly specified by the code and relates each one to its required wall rating, its corresponding minimum fire door and fire shutter assembly rating as well as the building code ratings and requirements relating to the vision panels, sidelites and transoms found in them. It then goes on to provide comprehensive listings of all the markings that must be found on the different types of fire rated glazings that may be used in those assemblies.

Table 716.6. This table addresses fire window assemblies. Like Table 716.5, it provides a listing of the fire-rated wall assemblies where fire-rated windows may be found, the corresponding wall assembly ratings, the associated minimum fire window assembly ratings, and the markings that must be found on the fire rated glazings used in those assemblies.

Source: US Glass Magazine, January 2013