SAFTI FIRST Architectural Glass Products Bring Exciting Innovations for the Architectural Community

With many years of experience, over sixty in the architectural glazing industry, we have learned that innovation is a necessity to growth and success both for our clients and ourselves. The architectural community rewards innovation and appreciates evolving architectural advancements as this innovation allows them to introduce interesting, new, and creative projects, whether an application, performance, safety, aesthetics, or environmental innovation. The architectural community is a leader in creating many groundbreaking solutions by pushing glazing manufacturers to create new products and solutions to improve and enhance their creations. This includes their request to combine performance, energy efficiency, code requirements, design, and lower lifetime costs into our products. These requests and desired combinations have created a track record of more efficient, sustainable, and architecturally enhanced products for projects worldwide.

SAFTI FIRST has responded to these requests for innovation in our systems and our manufacturing capabilities to bring these glazing innovations to fruition. First, by being the first to manufacture and bring fire rated glass to the USA that acted as a transparent wall, with ratings available up to 3 hours and the framing, doors, and entrances to accompany these ratings. We have created world-class facilities in Merced, California, to produce these USA-made products. This has allowed us to meet the ever-rising demand for clear, advanced fire rated glazing products while providing competitive pricing and fast lead times. Quality USA manufacturing also allows us to accommodate custom designs and a fast response to complex delivery schedules unmatched by foreign suppliers. The current supply chain disruptions have shown the advantage of having SAFTI FIRST, a fully integrated, USA manufacturing company as a supplier of these products.

This background in providing new innovations and in house manufacturing have allowed us, in turn, to advance and expand. SAFTI FIRST is excited to announce many new innovations and manufacturing capabilities.

New Capabilities

The newest capability added is the installation of a state-of-the-art Pujol 100+, a two-million-dollar, complete laminating line with one oven for standard lamination processes and one oven for bomb blast and detention products. This automated laminating line is capable of manufacturing almost any variation of laminated glass products. These include: Bullet-Resistant, Blast, Hurricane, Forced Entry/Attack, Switchable and Dynamic Glass, Art Glass, Glass Floors, Glass Stairs, Glass Railings, Mirrored or One-Way See Through Glass, Decorative Glass with Organic Inserted-Fabric, Metals, Stones and Papers, Colored Glass, LED Glass, Bird Friendly Glass, Glass with Ceramic Frits, T.V. and Internet Mirrored Glass, Vandal Protection, Decorative, Energy Performance, and Sound Rated Glazing. Each of these options can be mixed or added together to create a multi-functional, high-performance glazing system that can incorporate fire ratings up to 120 minutes, providing architects with the maximum flexibility for their specific needs.

New Innovations

SAFTI FIRST innovations are many and varied this year. They include SAFTI FIRST’s development, testing, and listing of a new innovative curtain wall system. This patent-pending Panelized “SAFTI-EZ-ARC”, recently successfully tested and listed by U.L., is designed for use in non-rated or rated applications, with fire resistive ratings up to 2 hours and more scheduled testing to meet hurricane, blast and tornado requirements.

SAFTI FIRST innovations are many and varied this year, including the development, testing, and listing of a new innovative curtain wall system. The patent-pending “SAFTI-EZ-ARC” is the first USA-made, truly panelized, versatile structurally glazed curtain wall system. Two versions were developed to satisfy non-rated and fire rated applications: SAFTI-EZ-ARC is a unique panelized system that will provide ease of installation in a curtain wall, while the “SAFTI-EZ-ARC-FR” is an ASTM E-119/UL 263 fire resistive rated version recently successfully tested and listed by U.L. up to 2 hours. Additional testing is scheduled to meet hurricane, blast and tornado requirements.

This panelized non-rated and rated systems can be used alone or married together easily for seamless unbroken sight lines. This is breakthrough product that provides architects, owners, and façade consultants with the greatest flexibility of design, and engineered a panelized system to lower costs and provide ease of installation.

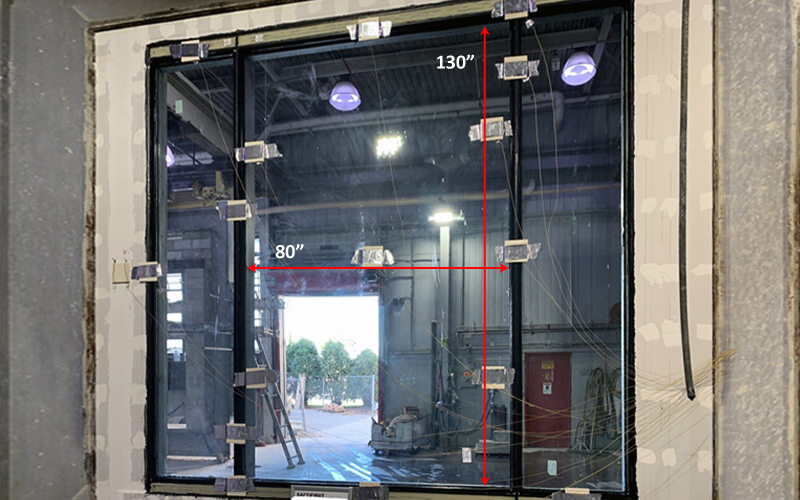

The “SAFTI-EZ-ARC-FR” panelized curtain wall is the largest fire rated glazed areas available listed by U.L. at one hundred thirty inches high and eighty inches wide (130” x 80”) for each individual panel for the rated areas. For non-rated areas, the sizes are even larger.

These large, non-rated “SAFTI-EZ-ARC” or rated “SAFTI-EZ-ARC-FR” fire resistive ASTM E-119 wall panels can be mixed together up to their maximum engineered size. All this with a pleasing, slim two-inch (2”) profile sight line. SAFTI FIRST anticipates this capability will be extremely popular with architects in allowing unmatched design flexibility with energy performance, decorative or security options, ballistic, blast, hurricane, etc. Both of these products will provide versatility, cost savings, and ease of installation with the additional option of fire ratings up to 2 hours.

Before 2-hour fire test:

During 2-hour fire test:

After 2-hour fire test and the full hose stream:

More Innovation

SAFTI FIRST’s innovation has also been directed at residential high fire risk areas with the development of “SAFTI Fence,” a Glass Fence Rated Up to 1 Hour. “SAFTI Fence” is bringing innovation to an area of growing concern by taming wildfires that can devastate these high fire risk areas. A product first tested and brought to market for use in Southern California in areas where views interfaced with fire zones along coastal areas. This allowed clear, unobstructed views while also providing security from fire and giving property protection. “SAFTI Fence” has recently received a 1-hour rating by Intertek. This “SAFTI Fence” by SAFTI FIRST is a clear, high impact safety glazing. A fence that can surround an entire residential development or single homes in urban wildland areas providing security, fire protection, and the added benefit of sound or animal control. SAFTI FIRST’s “SAFTI Fence” is proudly USA-made and tested to a 400-pound impact or higher in a laminated version. It can be provided in personalized laminated options, decorative, colored, satin etched, bird or animal friendly patterns. Fire insurance premiums may be reduced in some areas due to the additional fire and security protection provided.

New Innovation on an Old Product

SAFTI FIRST is also introducing another game-changer for the 20-45 minute fire protective market. This market segment is currently dominated by hollow metal framing because architects and owners do not have an aesthetically pleasing, affordable and easy-to-install fire protective framing system – Until now.

SAFTI FIRST is gearing up to launch our patent-pending “GPX SnapCap” framing system. This revolutionary new framing system will have the sleek, clean, uniform sightlines as non-rated aluminum storefront. It is available in multiple finishes including standard and custom finishes, including anodized. Designed for easy installation, the “GPX SnapCap” framing system reduces field labor costs. They can be installed after all the openings are done, making it perfect for both new construction and renovations. With all of these benefits available at a competitive price, SAFTI FIRST believes that the “GPX SnapCap” will make hollow metal frames virtually obsolete.

The “GPX SnapCap” framing combined with SAFTI FIRST’s patent-pending SuperClear 45-HS (hose stream) and SuperClear 45-HS-LI (hose stream, low iron) glazing products provide architects and owners with a complete, aesthetically pleasing and affordable 20-45 minute assembly that replaces outdated and expensive wired and ceramic glass in hollow metal frames.